Old mills that possess settled right into stream dirt, retail properties that come through seasonal freeze, medical facilities along with vulnerable enhancements tied to existing basements, each of these projects pushes the very same inquiry: how do you transmit lots to competent dirt without tearing the residential property apart or tying up procedures for full weeks? Helical piles respond to that question most of the time. They bite in to the ground with predictable torque, they put up fast with little equipment, as well as they let you keep working upstairs while the base gets more powerful below.

I learned to count on helical devices in limited metropolitan streets and inside active plants where noise and also resonance were actually the foe. The first time you view a crew specified steel shafts due to the numbers of, every one analysis like a twist scale, you begin to watch deep foundation repair as a controlled method rather than a small digging battle. They are not universal, and I will certainly clarify why, yet when soil, get access to, and bunches line up, commercial helical pile installation can easily squeeze schedules and also lessen threat in a manner pierced or driven options battle to match.

What "streamline" truly indicates on a business site

Streamlining appears in 3 ways consumers experience promptly: speed of mobilization, very little disorder, and predictable ability. Helical piles do certainly not require remedy opportunity like concrete, as well as they perform not call for huge rigs or even pile-driving hammers. A skid guide or small bulldozer with a hydraulic ride scalp can establish turn in constrained courtyards or even with piece positions, at times along with headroom under 10 feet. The actual win is that each heap's installation torque correlates to soil stamina, so you do not wait on a lab test to know whether your assumptions support. If twist falls short, you incorporate coil sections or even breakthrough deeper till you hit the target.

On a convenience store where the chilled aisle slab had settled down 2 ins over a power trough, our team put in 28 helical piles as well as brackets after hrs. The shop opened each morning without orange fence or even jackhammers. That would certainly possess been unthinkable with driven wood or a big drilled system. The work was cleaner, which matters when you are actually functioning around meals storage space or even health care environments.

Where helical piles accommodate among deep-seated base options

Helical piles do certainly not live in a vacuum. They compete as well as usually coincide along with micro piles, resistance heaps, as well as dirt supports. A short background helps border the give-and-takes.

Micropiles are tiny size bored and also grouted aspects that excel in hard geography or high tons situations. They function in cramping spaces and also around existing groundworks, but they demand exploration, grouting, as well as usually a grout remedy time frame before filling. Commercial micro pile installation polishes when you need rock-socketed capacity, uplift resistance in very loosened filler, or even when the ground account features cobbles that may harm helical plates. The devices impact may be sleek, however the process includes more actions and consumables than helical systems.

Resistance stacks, likewise called push piers, are actually steel sections jacked in to the ground using the establishment's weight as reaction. Commercial resistance pile installation is efficient for underpinning when the building may deliver the reaction pressure. Their capacity relies on readily available building payload throughout set up, as well as in lightweight construction or even predisposed underpinning cases, that constraint may make complex concerns. They are actually superb for structural foundation repair where gain access to is tight as well as sound needs to be minimal.

Helical tieback anchors offer sidewise assistance. When a foundation wall accepts or a deeper digging needs supporting, commercial helical tieback anchor installation lets crews string anchors via the wall structure or even soldier shaft as well as turn all of them right into steady dirt, after that secure off along with platters or even grains. Unlike grouted tiebacks that need connect zone screening as well as cure opportunity, helical tiebacks can be tensioned immediately after setup when problems are suitable.

Viewed with each other, the choice is actually rarely regarding trademark name. It turns on soil conditions, lots requirements, get access to constraints, timetable stress, and whether the design needs to have upright support, lateral caution, or both.

Soil, torque, and also style, the heart of helical performance

Helical stacks function by raising several steel coil plates joined to a central ray in to carrying strata, at that point transmitting building lots down the shaft to those platters. The center natural sciences are actually simple: as the helix puncture soil with a pitch comparable to a screw, it displaces low component and also activates end-bearing as well as skin layer rubbing. Installment torque connects to supreme capacity with empirical partnerships that have many years of field verification. For experts, the torque-to-capacity proportion, typically in the series of 8 to 12 foot-pounds every kip for popular bar measurements, comes to be a real-time gauge. Our team agree on a target twist throughout concept, then confirm it in the field.

Design requires care. Layer space usually equals 3 times the coil size to prevent interference of stress and anxiety bulbs. For example, an 8-10-12 inch triple-helix collection could be spaced 24 ins apart along the shaft. The main shaft might be a straight bar, mention 1.5 inch for founding brackets, or even a rounded weak section for higher bending over requirements. Deterioration defense, hot-dip galvanizing or even sacrificial steel density, must be actually adapted to ground chemistry and service life. I have taken piles after 15 years in mildly aggressive dirts that appeared just about unmarred, and also I have actually viewed piles in particular marine clay-baseds that needed to have thicker sacrificial allotment from time one.

The setup pace concerns. Too swiftly, and also you risk dirt disturbance as well as imprecise torque readings. As well slow-moving, and also you shed productivity. On most jobs, a veteran operator secures a consistent development of approximately one change per second while keeping track of pressure. A twist monitor mounted at the ride head maintains everybody truthful. When the musical instrument reads through less than assumed and also the ground log advises a lens of softer residue, you possess choices: continue much deeper to the next experienced level, change to a different coil configuration, or even pause and also get in touch with the designer. Along with steered stacks you might certainly not uncover the very same unpleasant surprise till after a vibrant test, as well as along with bored shafts the variability can conceal in the slurry, only to turn up in the course of tons testing.

Installing in online centers, a real advantage

Commercial groundwork fixing commonly takes place inside occupied buildings. Helical piles and helical anchors make good sense listed below given that they make little bit of vibration and also small sound. A school gym along with a tossing piece over large clay is actually a good example. Our experts cut rectangular openings in the slab, excavated tiny pits, set up heaps with void posts to prevent uplift on the piece throughout rotation, then attached brackets to the level shafts. The janitorial workers vacuumed just before the baseball team showed up. No center drilling for rebar crates, no cement hoses operating 100 feet via hallways.

Hospitals as well as records facilities love resonance. Quick ruptureds of torque from a gas ride head rarely register on a seismograph contrasted to even a small impact hammer. If the center possesses mission-critical operations, helical units let you arrange around all of them rather than shutting them down. That versatility often offsets a somewhat much higher system cost contrasted to some steered possibilities, given that you stay away from costs change job and also complex control along with tenants.

Underpinning worked out groundworks with precision

Settled structures tell their own tale: diagonal drywall gaps, adhered doors, home windows that need to have a bodyweight hip-check to finalize. Foundation crack repair may address noticeable signs, yet when the underlying ground has actually dropped enduring capability or gone through unification, gaps come back. Underpinning along with helical piles or resistance stacks stops the activity and also provides a measured lift when appropriate.

We assess whether the property can put up with airlift. Stonework may crack if raised unevenly, specifically near re-entrant edges. We usually stage piles along the footing at 4 to 8 foot spacing, put up braces, at that point pre-load each heap incrementally. A manifolded gas unit allows concurrent lift throughout a wall. One warehouse our team assisted had interior shelfs packed to the rafters, so we confined assist to 5/8 inch and also paid attention to stablizing, not total rehabilitation of degree. That selection maintained protection and always kept functions in one piece. Commercial foundation stabilization United Structural Systems of Illinois, Inc helical piering is actually certainly not a binary choice between best and failed; it is usually a calibrated adjustment along with common assumptions in between proprietor, developer, and also contractor.

Resistance piles conduct likewise in a lot of underpinning scenarios. When a building is actually massive enough to supply sustained response, push boat docks can easily connect with serious bearing strata quickly. Helical piles provide a clearer read of ability during put up via twist, which aids when footing loads vary or when simply component of a building is being actually sustained. In soft clay profile pages along with reduced skin layer rubbing, helical plates can interact deeper qualified layers without excessive shaft span since they perform certainly not rely solely on skin layer friction.

Lateral tons and also helical tieback anchors

Retaining wall surfaces that pitch or even basement wall surfaces that accept, these are actually issues of sidewise tension surpassing protection. Helical tieback anchors fix this through evolving a multi-helix support via the wall surface and also into stable soil responsible for the active block. Once the support reaches aim at twist, our team fasten a bearing layer and pressure the pole. Given that tensioning can easily take place immediately in coarse-grained soils without cementitious bonding, commercial helical tieback anchor installation lessens the timeline contrasted to grouted supports that require a cure window.

A typical breakdown factor is the wrong angle. As well shallow, and also the support lives inside the failure wedge, performing bit great. Also steep, and also you miss one of the most effective bunch course and also make complex setup inside cellars. Experienced workers test a fly support to verify both torque as well as lots transfer just before putting up the variety. In natural grounds, we sometimes pre-drill a brief pilot to lessen disturbance at the wall penetration, then permit the helix to reduce its own course in the connect area. The reward is actually prompt wall surface stabilization along with expected tons and also very little mess.

Micropiles for the side scenarios helical piles may not reach

No single system handles every problem. Micropiles make their inhibit boulder-laden tills, where coil plates may hang up or even bend. Rock outlets, where the developer wishes a determined bond duration in stone instead of bearing in ground, are traditional micropile region. In seismic retrofit job where detailing and plasticity matter, a grouted steel core along with confirmed bond spans answers structure officials and peer consumers along with confidence. Micropile installation manages above constraints also, usually along with electric drill motors as well as sleek stands that match through doorways.

The give-and-take is actually complexity. You should take care of spoils, cement, connect zone cleansing, and also treatment opportunity just before loading. On a fast-track retail fit-out, that series may stretch timetables. On a bridge abutment with high lots and changeable strata, those same measures acquire certainty. Understanding when to promote for micropiles, also when your team enjoys helical velocity, is actually the result of a liable contractor.

Speed, price, as well as ability, taking a look at the numbers

On common industrial groundwork in accessible grounds, a two-person team with a small digger can easily put up 10 to twenty helical piles every day, occasionally extra with repeated problems. Industry productivity for micropiles could land closer to 4 to 8 daily, depending upon dimension, depth, and also exploration problems, with extra opportunity for cement cure. Protection piles can easily match helical productivity when the structure delivers adequate response and also the dirt profile page is uniform.

Cost per heap differs commonly based on intensity as well as deterioration protection. Usually of thumb, helical piles with regular galvanizing and midsts of 20 to 40 feets fall in an intermediate range that remains reasonable against pierced or steered devices when you make up internet site repair and also timetable. When priming upgrades, bigger bars, or deeper installs are required, the unit price growths, yet the amount of time savings as well as take the chance of reduction commonly maintain complete job price desirable. The best dependable comparison is complete put in price to accomplish required ability with satisfactory threat, certainly not worldly rate every foot.

Capacity is not guesswork. Our team point out twist criteria based upon previous medical history and also verified screening. In high-stakes jobs, our company manage compression or even stress lots tests Commercial Helical Pile Installation on propitiatory or production heaps to call in the torque-to-capacity element for that dirt. I have observed elements vary from 6 to 14 foot-pounds per kip depending upon shaft, helix configuration, and also soil plasticity. When an examination reveals a reduced factor than presumed, the fix is actually uncomplicated: rise deepness to interact more powerful soils, add coil layers, or even transform shaft dimension. That clarity reduces change purchases and also arguments.

Foundations along with combined roles, incorporating upright as well as side systems

Urban ventures commonly require both vertical help and side restraint. For example, a brand-new escalator center connected right into an aged structure could hinge on helical piles for vertical lots while temporary helical anchors keep a cut cellar wall surface throughout digging. The balance between professions issues. Our company stage anchor locations so they carry out not conflict with stack limits, and also our team pull exam supports early so the excavation schedule stays intact.

In waterfront work with surge or even flood uplift parts, helical piles polish once more due to the fact that their helix platters may stand up to uplift and also compression. Designers at times utilize the exact same stack group to stand up to both, however you helical piering require matched groupings and hookups to take care of pressure. In destructive soils, priming and, if needed, epoxy coverings secure long-term functionality. Conversations along with the geotechnical engineer about redox capacity and also chloride web content, certainly not merely common ground style, aid adapt the rust plan rather than depending on quilt assumptions.

Structural information that make a decision success

Connection details make or damage structure repairs. Underpinning brackets have to seat easily under the footing, which indicates chipping to appear concrete, shimming correctly, and confirming rebar locations to steer clear of damages. A typical blunder is actually setting a bracket on shabby concrete, at that point wondering why an airlift generates spalls or uneven bearing. Our company often utilize little ground-penetrating radar to map rebar and reduce surprises.

Pile caps for new development on helical piles ought to have the exact same respect you offer bored shafts. Installed layers, seams, as well as rebar development durations should match designer intent. When heaps are actually ruined for lateral capacity, those angles show up in limit specifying. Bypassing a bar or even diminishing edge ranges to fit an anchor bolt can trash the move pathway. Installers enjoy to relocate rapidly, but the job benefits when you slow down for the initial number of hats and set up a template.

For helical tiebacks, the wall layer or even ray of light relationship need to spread tons. Brickwork wall surfaces along with questionable cement fill need to have verification boring or even through-bolting to steel grains. Tensioning operations ought to be consistent: seating lots to begin with, at that point locking at concept tons, along with determines adjusted as well as logged. When lots rest after a time, it is frequently soil creep, certainly not anchor lapse. Re-tensioning to a somewhat reduced lock-off can support the device without magnifying the wall.

Handling energies, contamination, and various other real-world headaches

Most commercial web sites conceal energies you would rather not meet a drive head. Electromagnetic finds aid, however they miss out on unmarked pipes. Vacuum potholing at critical pile or even support sites purchases on its own the first time you stay clear of a fuel pipes or even fiber package. Our experts also present a plan for spoils despite helical work, given that you still dig deep into little pits at brackets or hats. In older commercial internet sites along with lightweight poisoning, dealing with those spoils via drums and also shows up may affect which unit you pick. Helical and also protection stacks keep spoils reduced compared to bored possibilities, which decreases ecological managing costs.

Access courses matter. A 12,000-pound bulldozer carries out not float all over a tile entrance hall. Temporary mats, bunch estimates over basement slabs, and in some cases a switch to electric-powered drive directors avoid seethes and floor damages. On a museum makeover, our team took tools with a loading dock, worked within strict sound windows, and also safeguarded art storing with unfavorable sky equipments despite helical's reduced dust. The superintendent rested much better, and so carried out the contributor associations team.

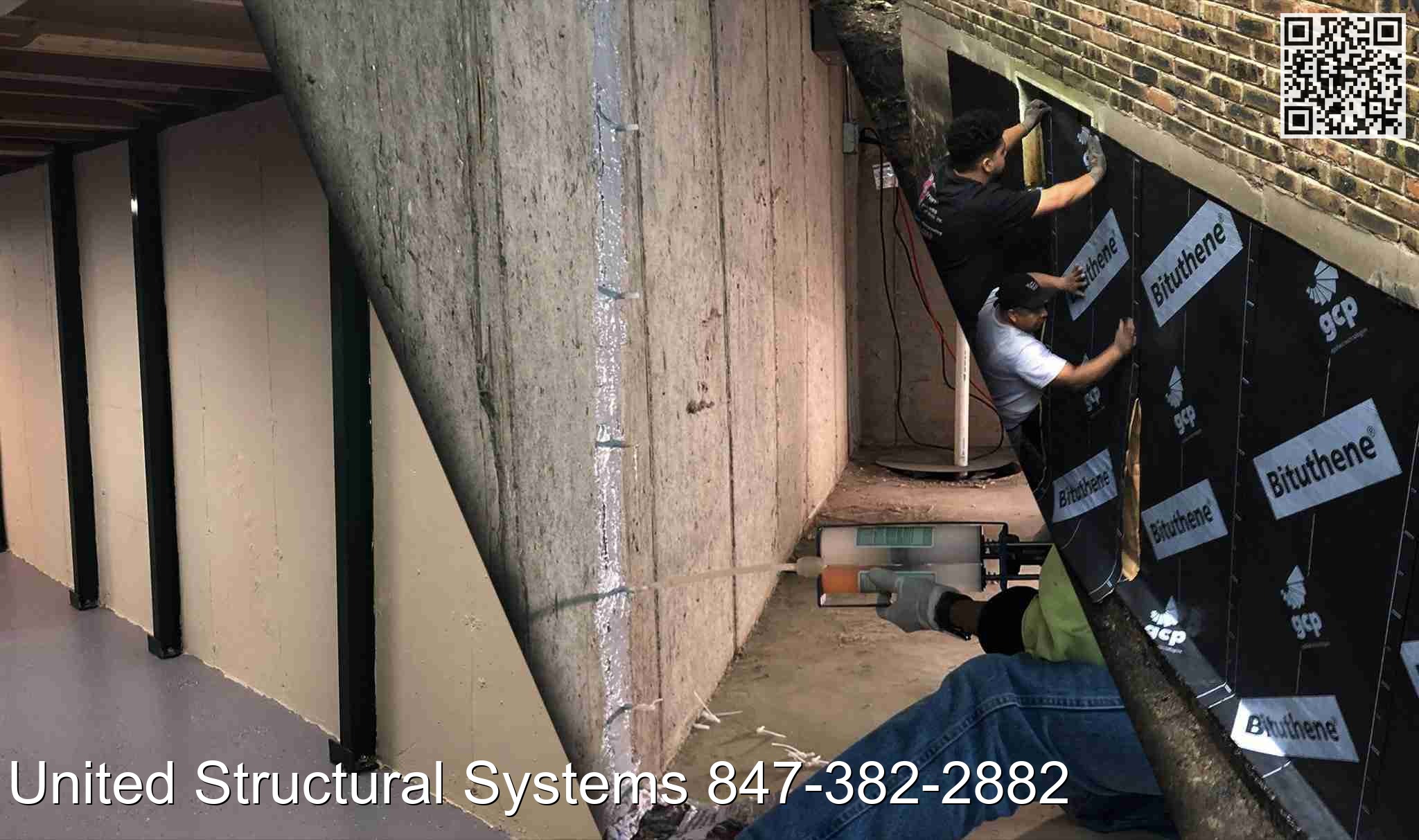

Integrating foundation crack repair with serious supports

Owners often begin the talk along with a gap. Epoxy treatment, polyurea caulks, as well as carbon dioxide fiber straps all have their area, yet they are actually bandages if the dirt maintains relocating. Our company advise sequencing: stabilize initially along with helical piles or resistance piles, after that recover wall integrity. When we mount helical tieback anchors for a stooping wall, our team couple them with indoor carbon dioxide fiber or even steel network encouragement to disperse tons and also protect against neighborhood reducing at birthing plates. Area gap repair adheres to, and also in many cases our team leave behind a surveillance gauge to document periodic movement. The point is to make the wall structure aspect of a stronger tons path instead of a sufferer of dirt pressure.

Quality control without drama

Good installments feel boring, in a comforting method. The foreman shouts twist readings every number of feets, the lumberjack documents deepness, coil arrangement, and also final twist, and the designer witnesses critical turning points. If a pile stalls or twist spikes early, our experts stop as well as identify as opposed to multiplying adverse hydraulic tension. Sometimes a shallow obstacle needs elimination or a revised coil pile. When we assess, we set up clean jacking frameworks, adjusted determines, and also dial indicators, certainly not eyeballed referral factors. Most load examinations pass when the layout is bared in ground information and also the crew appreciates procedure.

Documentation concerns to potential you. 10 years after a task, an owner might phone along with an expansion program. If your as-builts present places, midsts, capabilities, and deterioration protection, new work includes perfectly. If all you left behind is actually a salary document, finding switches expensive.

When to advise something else

Helical stacks struggle in cobble-laden frosty till as well as in timeworn stone where coil platters may not cut easily. If twist climbs up too soon at shallow sharpness as well as does certainly not connect to ability, you take the chance of a false favorable. In those health conditions, a micropile with a rock outlet or a punched boat dock creates more feeling. Similarly, if you need to have very high single-pile capacities, say above the variety typical helical poles support without twisting, micropiles or even drilled bars end up being a lot more efficient every kip. Noise-sensitive internet sites with incredibly stringent electromagnetic disturbance policies might frown on hydraulic electrical power devices, though electrical heads alleviate that.

Floodplains along with aggressive corrosion also require added thought. Galvanizing and sacrificial steel might suffice for 50-year life in a lot of grounds, however in chloride-rich settings you might incorporate epoxy covering or even cathodic security. That includes cost as well as intricacy. I have actually transformed ventures far from helicals when the lasting rust strategy felt even more contrived than robust.

A practical, phased approach to office foundation repair

Owners and layout groups value a program that recognizes finances and disturbances. A regular series that works effectively:

- Investigate: geotechnical borings or even test pits near concern locations, gap mapping, amount questionnaire, as well as customer review of drawings. Pilot installment: a handful of manufacturing heaps or even anchors with bunch exams to validate twist factors and details. Phased job: prioritize crucial zones, correlative with residents, and also always keep day-to-day impacts small. Restoration: full foundation crack repair, patch slabs, repair work coatings, and also establish monitoring points. Maintenance: periodic twist spot checks on left open supports if appropriate, and also an easy log of seasonal movement.

A phased strategy allows stakeholders view development as well as minimizes surprises, which matters more than any solitary modern technology choice.

The benefit for the job team

Commercial helical pile installation, paired smartly along with resistance stacks, micropiles, as well as helical tieback anchors, gives contractors a pliable toolkit for deep foundation repair. The value is actually not simply quicken. It is actually the reduction of unknowns. With torque as a proxy for ability, with marginal spoils and also vibration, and with urgent bunch transmission in a lot of grounds, you acquire a tighter reviews loop between layout assumptions as well as area fact. That loop steers much better decisions, fewer adjustment purchases, and ventures that complete without drama.

I maintain one image on my phone from a wintertime task at a factory. Snow boiling down, a portable backhoe put inside a gulf door, driver setting heaps while forklifts zoomed behind him. Through advanced afternoon the brand new row line was sustained on helicals below the frost line, brackets bolted, caps positioned, and also the vegetation kept shipping. No major headings, only trustworthy development. That is what efficient deep foundation repair appears like when you obtain it right.